The automatic duct line III is a complex piece of machinery consisting of a decoiler, leveling and grooving rollers, a hydraulic notching and punching mechanism, a hydraulic shearer, and a hydraulic folder. The electrical control system utilizes a powerful computer with a closed-loop servo-system to greatly increase the precision and reliability of the line. The rectangular air duct ADL-III is our most popular model because of its good balance in performance and investment cost. Processed sheet metal width can be 1300mm or 1600mm, based on client preferences. Through the use of a PLC control system, the machine performs automatically to produce a semi-finished air duct. Free training is provided at our plant, technicians are also available for on-site installation and commissioning by request.

Technical Specifications

Max. working speed: 10m/min

Suitable plate thickness: 0.4-1.2mm

Max. plate width: 1300mm

Tolerance in length: +/-0.5mm

Tolerance in diagonal: +/-0.8mm

Working capacity: 1000m² square duct per shift.

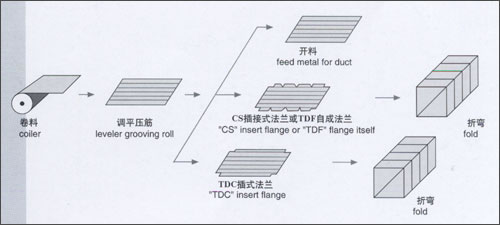

Flow chart

BOBO Machine is a China-based automatic duct line manufacturer and supplier. We also offer spoke and nipple machine, corrugated pipe machine, air filter hot press machine, among others.